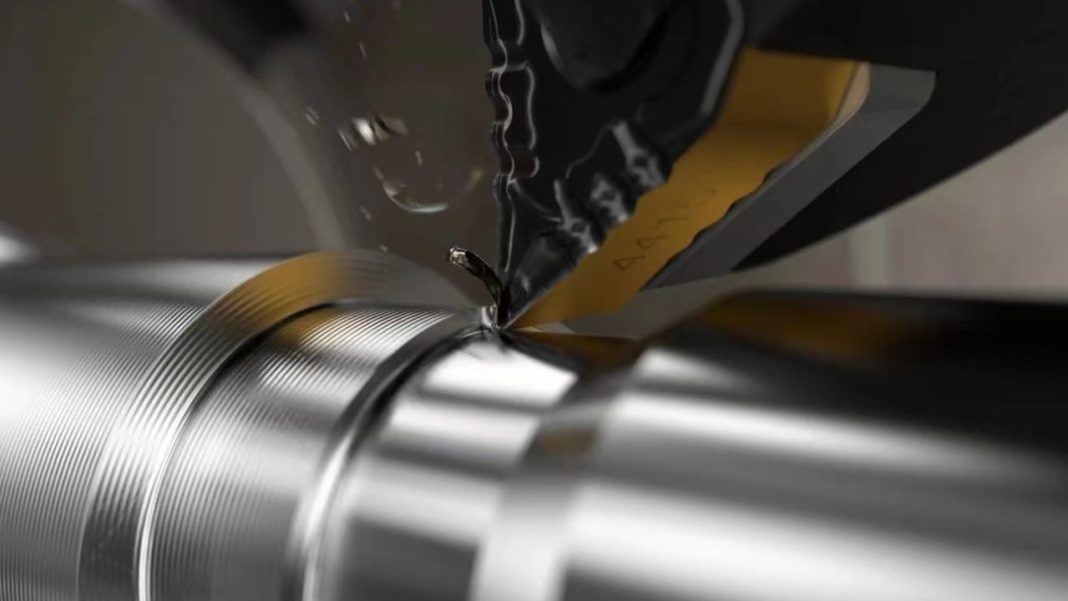

You cannot overemphasise the importance of custom cnc machining parts. The term custom reflects the product featuring a complete level of personalisation. In such components, you can change the shape, specs, dimensions, structure, and finishing depending on your needs. Customisation provides a key to the innovation.

Industries need customisation to manufacture innovative products. It also serves as the key to incredible technology updation and advancement. To cater to appropriate customisation in cnc products. The reputable manufacturer plays a key role. 3ERP is your go-to solution in this regard.

3ERP – Short Intro

The 3ERP is a cnc machining manufacturer that can help you craft remarkable cnc machining parts. 3ERP can help you with the process from zero to hero. An option exists to order prototypes. The key services of the 3ERP vacuum casting, 3D printing, rapid tooling and injection moulding, CNC machining, and pressure die casting. Apart from this, you can also seek services for aluminium/plastic extrusion and metal sheet prototyping.

3E in the term 3ERP refers to Excellence, Economy, and Efficiency. This will clear the working motto of the manufacturer.

What Makes 3ERP Standout From The Rest?

Several benefits play a key role in this regard. Unveil the notable benefits in the following section:

Scalability

When working with the 3ERP, you can upscale your design anytime. This is true in terms of volume and shape. The possession of the latest and most advanced machines makes this possible on the go. The manufacturer has a built-in capability to manufacture above 10k up to 100k products a month. You don’t need to worry if you need several pieces for a particular design. 3ERP can help you achieve that on the go.

Value Addition

You will not get the products in raw form when selecting the 3ERP. This is because the 3ERP take care of the product in terms of value. It offers additional services such as assembling, coating, and product finishing. These services add up to the overall value of your product. This way, you can earn more by spending less.

Low Volume Manufacturing

3ERP mainly assists you in low-volume manufacturing. The term low volume manufacturing means lesser product quantity. This is good for those components that feature limited demand. You can deal with the prototypes and can perform quick revisions. The limited demand caters for you to experience quick iterations in the product.

Improved Surface Finish

Choosing the 3ERP among other brands and manufacturers can help you stand out from the rest regarding the product finish. This is because the 3ERP solely contributes to the incredible surface finish. 3ERP allow you to pick any finish regarding anodised coating, painting, powder coating, nickel plating, e-coating, etc. Choosing a specific type of surface finish can help induce certain properties in the product.

Low Cost

3ERP can help you to experience lower costs with your products. This is because cnc machining contributes to low material waste. This way, you can save the cost of the material and positively contribute to the environment. Low costs mean better ROI (Return on Investment). You will never going to repent of your decision in this regard.